“LEAVE IT TO CERTIFIED PROFESSIONALS TO HANDLE YOUR SCOPE”

Services

-

![Industrial manufacturing facility with stainless steel pipes, machinery, and equipment in a clean room environment.]()

Sanitary Welding

At Sons of Thunder Welding, we provide sanitary welding services for industries that demand absolute cleanliness and precision. Our TIG welding process ensures smooth, high-purity welds free from contamination, ideal for environments where hygiene is critical. Stainless steel process piping installation (304/316L)

-Orbital TIG welding for high-purity lines

-Manual TIG welding in tight-access or custom areas

-Fabrication and installation of sanitary tubing systems

-Welds with full purge and internal cleanliness control

-Polished or passivated welds for food-grade environments

-Clean-in-Place (CIP) system integration

-Sanitary valve and fitting installation (tri-clamp, ferrules, etc.)

-Field repair and modification of sanitary systems

-Installation of stainless steel tanks, hoppers, and drains

-

![]()

Industrial Fabrication

Our team specializes in the heavy-duty fabrication of custom steel components built to serve industrial operations with precision, durability, and job-site readiness. Whether it's a 5,000 lb stainless steel door, process ductwork, or support platforms, we fabricate complex builds in-house with expert fit-up, full welding capabilities, and field installation in mind.

-Stainless steel ductwork for cold storage and food processing facilities

-5,000+ lb stainless steel doors for industrial freezer and blast chambers

-Structural platforms, access walkways, and welded mezzanines

-Heavy-duty carbon steel frames, embeds, and machinery bases

-HSS beam assemblies with custom bracketry and field install prep

-Welded support structures for rooftop equipment, duct, and pipe systems

-Drain troughs, sumps, and custom box builds with TIG weld finishes

-Bracket systems for ladder support, cable trays, and conduit

-Fabricated stair systems with integrated railing and landings

-In-shop MIG, TIG, and flux-core welding for mild steel, stainless, and aluminum

-Transport-ready fabrication with lifting points and install coordination

-

![Close-up of a stainless steel connecting a vertical pipe to a flange, showing colorful heat discoloration. TIG welded joint.]()

Pipefitters

Our pipefitters specialize in the precise layout, fabrication, installation, and maintenance of piping systems for industrial, commercial, and specialty applications. We work with a wide range of materials including carbon steel and stainless steel to ensure systems meet the demands of high pressure, temperature, and chemical compatibility. Whether it’s new construction, plant maintenance, or system upgrades, we approach each project with a commitment to safety, code compliance, and long-term reliability.

-Steam and condensate lines for manufacturing and process facilities

-Chilled water and hot water loops in mechanical rooms

-Compressed air piping for production lines and industrial shops

-Sanitary stainless steel piping for food-grade and pharmaceutical use

-Chemical transfer systems using corrosion-resistant alloys

-Natural gas and propane distribution -piping for commercial kitchens and heating systems

-Hydronic piping systems in commercial HVAC installations

-Process piping for wastewater treatment and industrial plants

-Fire suppression system piping (black iron) in commercial buildings

-Pump skid piping fabrication and installation

-Prefabricated pipe spool assemblies with field installation

-Pipe hangers, supports, and insulation prep work

-Pipe welding (TIG, MIG, Stick) to ASME standards

-

![Stainless Steel welding near me]()

Stainless Steel

We provide expert stainless steel welding and fabrication services, specializing in creating durable, high-quality solutions for commercial and industrial applications. Whether you're in need of custom stainless steel components or repair work, our skilled welders use precision techniques to ensure strong, clean, and long-lasting results.

-Sanitary TIG welding for food-grade and pharmaceutical piping systems

-Fabrication and installation of stainless steel ductwork for cold storage, cleanrooms, and industrial HVAC

-Custom stainless countertops, sinks, and workstations for commercial kitchens and labs

-Stainless steel handrails, guardrails, and stair systems with polished or brushed finishes

-Welding and assembly of stainless steel tanks, vessels, and containment units

-Fabrication of marine-grade stainless components for harsh environment durability

-Installation of stainless exhaust systems and flue piping

-Custom stainless enclosures and frames for equipment and machinery

-

![Aluminum Welding near me]()

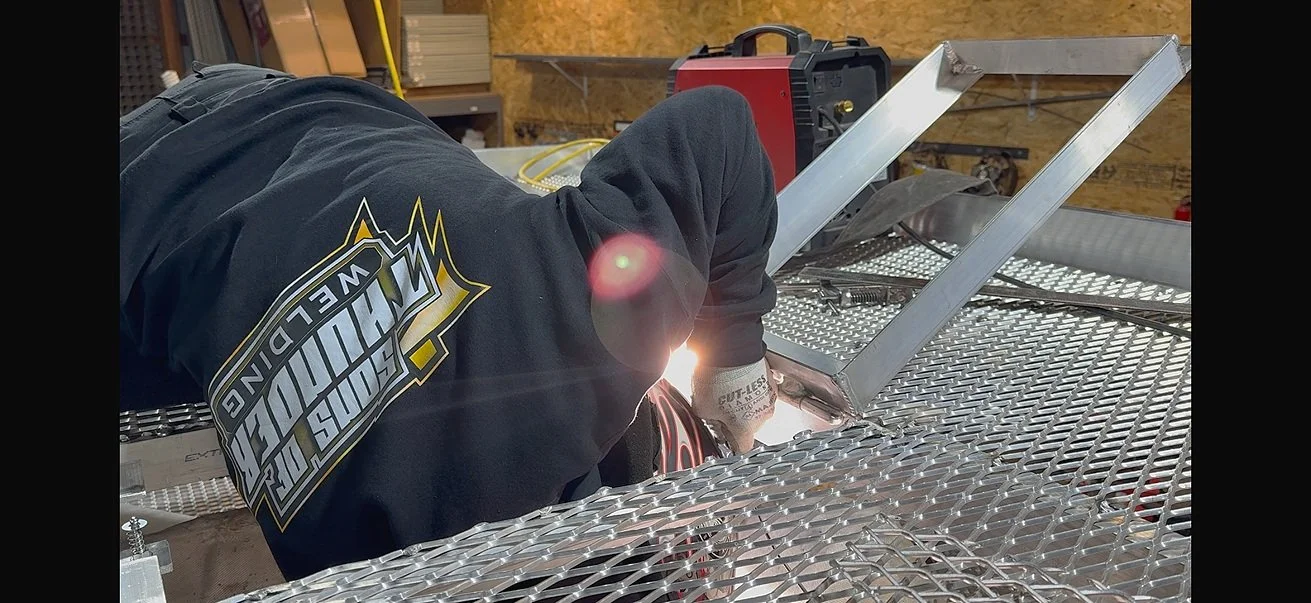

Aluminum

We provide high-quality aluminum welding and fabrication for a range of commercial and industrial projects. Whether you need custom aluminum parts or repairs, our skilled team uses the proper processes to deliver precise, durable, and clean welds for any application.

-Custom aluminum platform and catwalk fabrication for industrial facilities

-Welding and installation of aluminum handrails, guardrails, and safety ladders

-Fabrication of lightweight aluminum staircases and access structures

-Marine aluminum welding for boat repairs, docks, and yacht components

-Aluminum enclosure frames and housing units for mechanical and electrical equipment

-Architectural aluminum features such as sunshades, awnings, and trim elements

-Aluminum piping and tubing systems for low-pressure or specialty applications

-Precision TIG welding of thin-gauge aluminum sheet and tubing

-Structural aluminum frames for signage, supports, and modular assemblies

-Trailer and vehicle aluminum welding and repairs

-Custom aluminum fabrication for food-grade and cleanroom environments

-

![A person welding metal under a dump truck, wearing a welding helmet and hoodie with Sons of Thunder Welding logo.]()

Ironwokers

We specialize in a variety of miscellaneous steel construction projects tailored to meet the needs of commercial and industrial clients. From precision welding and fabrication to smaller-scale steel erections, we provide custom solutions designed for durability, safety, and functionality.

-Small Scale Structural steel erection for commercial and industrial buildings

-Setting and welding steel columns, beams, girders, and bar joists

-Field welding of connections per AWS D1.1 and engineer specs

-Installation of steel decking (welded and mechanically fastened)

-Anchor bolt setting and base plate leveling

-Installation of miscellaneous metals such as ladders, platforms, embeds, and stair systems

-Rigging and signaling for crane picks and heavy steel placement

-Erection of pipe racks, catwalks, and equipment supports

-Welding and installation of handrails, guardrails, and safety barriers

-Demolition and removal of structural steel as part of renovation scopes

-Pre-assembly and installation of bolted or welded steel trusses

-Installation of canopy, awning, and roof support structures

-

![Construction worker welding on the arm of a large excavator at a construction site with a gravel ground and cloudy sky. Cutting with oxy-acetylene torch.]()

Heavy Equipment

Our experienced team handles everything from equipment repairs to custom fabrications, ensuring your machinery operates at peak performance and meets safety standards.

-Custom fabrications for attachments and parts

-Welding and structural repairs on heavy machinery

-Equipment modifications and upgrades

-Hardfacing