Industrial Welding & Fabrication

Mechanical Systems

On-site welding and shop fabrication for industrial facilities — stainless, heavy steel, and plant repairs executed safely, scheduled responsibly, coordinated clearly.

What we Offer

“Maintenance + Reliability Support”

Structural Repairs & Safety Upgrades (rails, guards, platforms, ladders)

Equipment & Machine Welding Repairs (brackets, bases, frames, reinforcements)

Piping Repairs & Modifications (as applicable)

Skids, Supports & Custom Plant Fabrication

Planned Maintenance + Shutdown Support

Vendor-Ready Documentation

“What We Build”

Weldments

Platforms, Mezzanines, Stairs & Handrails

Machine Guards, Cages, Covers & Safety Barriers

Custom Brackets, Supports, Stands & Mounts

Stainless Fabrication

Repair / Reinforcement / Modifications to existing steel & stainless

“Repeat Production Support”

Repeatable Production Parts & Small Runs

Fixture & Jig Building for Consistent Fit-Up

Cut, Fit, Weld, Grind & Finish to Spec

Quality Checks

Packaging / Labeling / Deliver-Ready Prep

Supplier Support When Your Shop Is Overloaded

“Install + Modifications on Site”

On-Site Install of Shop-Fabbed Assemblies

Structural Tie-Ins, Reinforcement & Modifications

Equipment Mounts, Supports, Brackets & Anchors

Piping Supports / Hangers / Base Steel (as required)

Shutdown / Planned Maintenance Welding Support

Clean Work Areas + Closeout Photos / Punch List Completion

Built to Serve. Welded to Last.

We’re not your average welders — we’re your industrial support. Sons of Thunder Welding specializes in stainless steel fabrication, shop manufacturing, and on-site welding for industrial facilities that demand strength, precision, and zero compromise. Cold storage, processing plants, data centers, and large-scale industrial facilities — whether it’s in the field or built in our shop, we’re in the trenches getting it done.

But we’re not just about the welds. Our biggest priority is serving our customers and building strong relationships through the day-to-day grind. We don’t just work for our clients — we partner with them, tackling challenges side by side, from concept and fabrication to final install.

From shop-fabricated assemblies and custom stainless components to massive duct systems and critical process piping in the field, we bring hard-earned experience and craftsmanship to every job. We don’t cut corners. We don’t ghost jobs. We execute at the highest standards — every time.

industries served

Cold Storage

Data centers

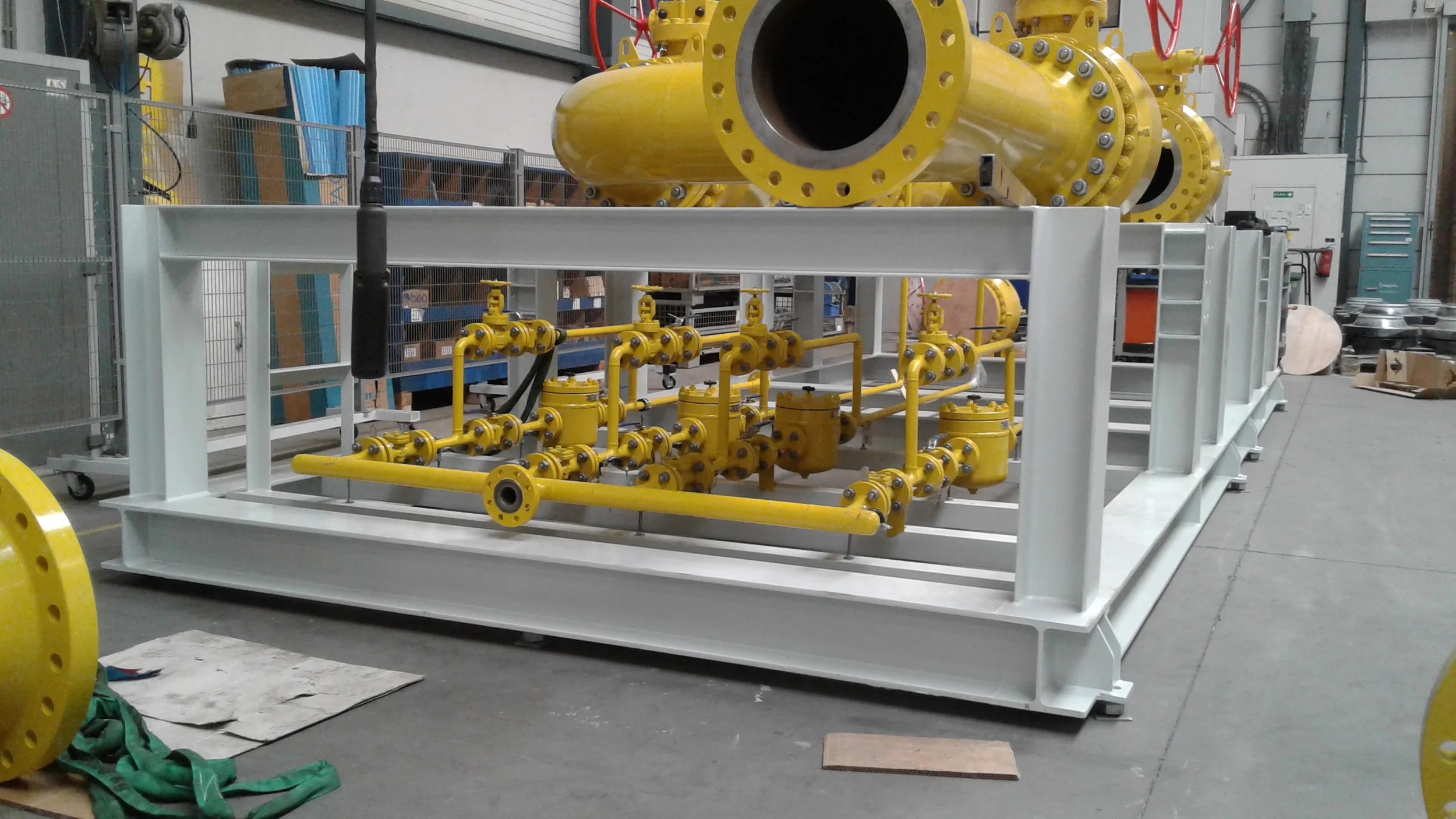

Oil and gas

FOOD AND BEVERAGE

HOSPITALS

CHEMICAL PLANTS

LIGHT INDUSTRIAL

POWER PLANTS & ENERGY

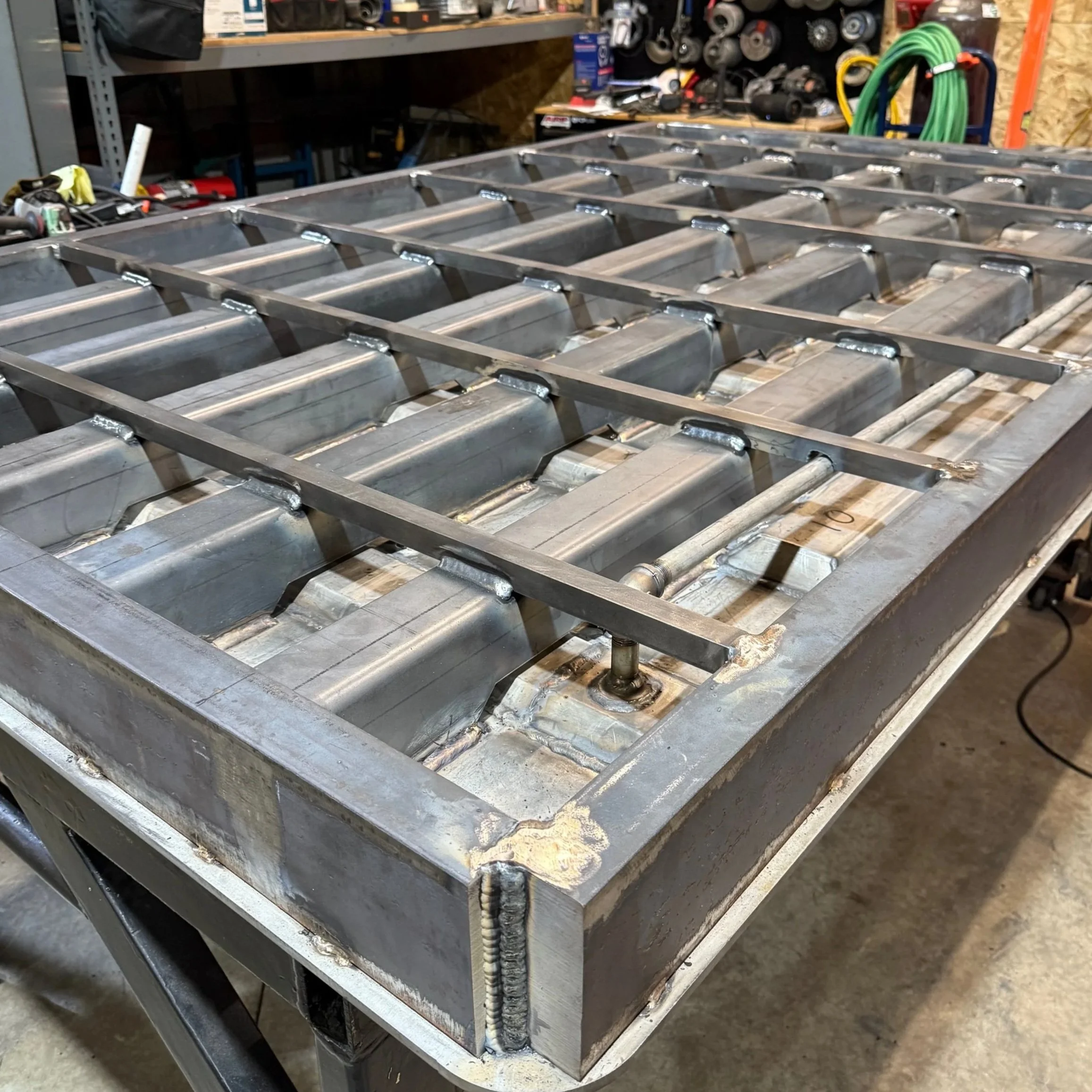

HERE ARE 6 HUGE INDUSTRIAL DOORS AND FRAMES WE HELPED OUR CUSTOMER FABRICATE ON A TIGHT SCHEDULE!

IT WAS A DOOR FULL OF STAINLESS STEEL WITH SPECIALIEZED HEATER CHANNELS AND PIPING

THE DOOR HAD A BUNCH OF BRACING, IT WEIGHED OVER 3500LBS!

THIS IS THE 1 OF 6 DOORS ALL FABRICATED

OUT TO THE CUSTOMER TO GET INSTALLED

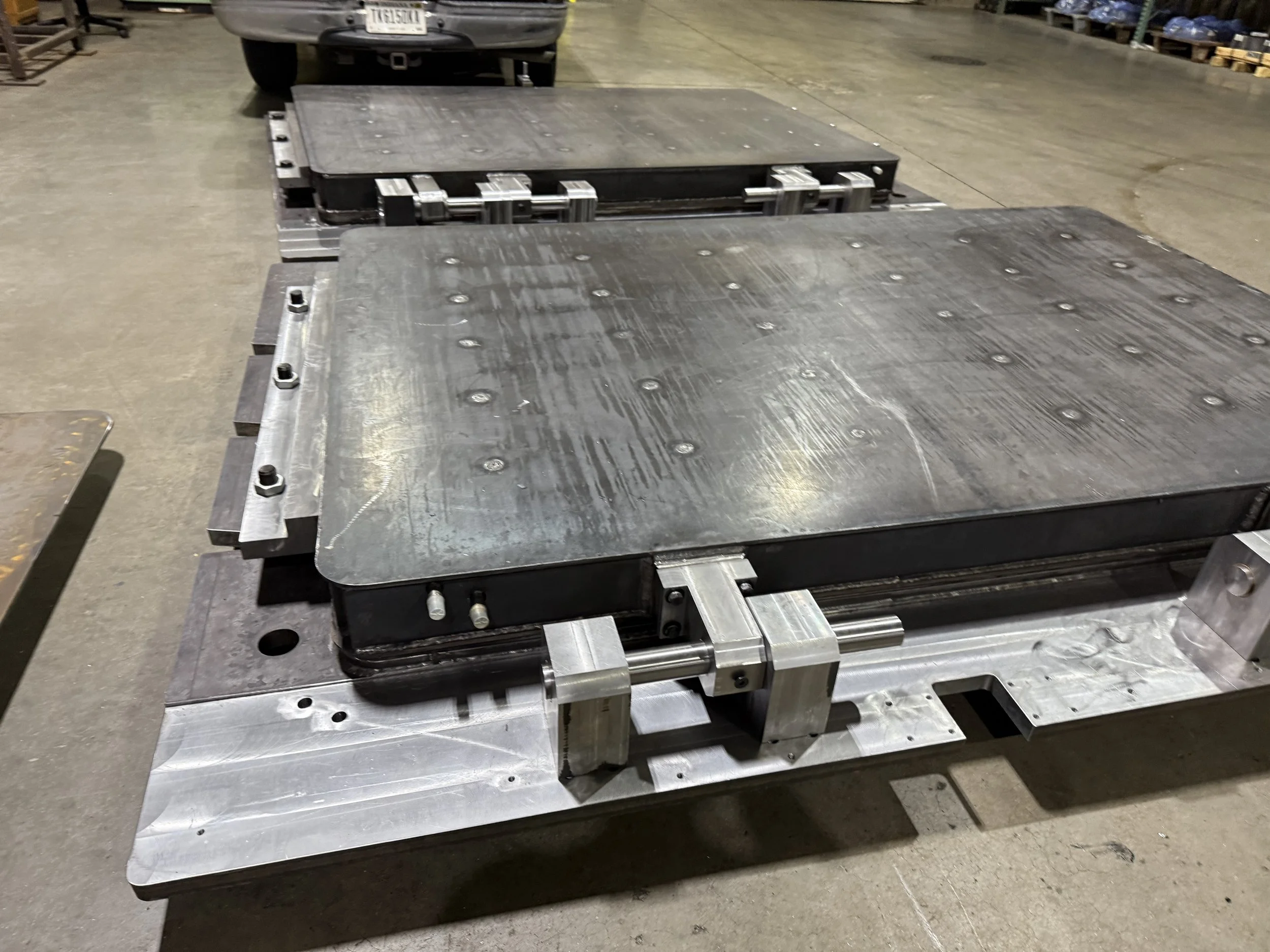

THESE WERE THE FRAMES TO THE INDUSTRIALS DOORS, REQUIRED HEAVY DUTY STIFFINERS TO REDUCE WARPPING

CUSTOM I-BEAM TABLE TO CLAMP DOWN AND WELD TO REDUCE WARPING

SONS OF THUNDER AT UNITED STATES COLD STORAGE!

34" FRYER DUCTS GETTING WELDED UP ON SITE

WELDING THE DUCT ON TO THE FRYER

HAVE TO GET IN THOSE HARD TO REACH PLACES WHILE STAYING SAFE AND WELDING PRECISE

FINISHED PRODUCT; RAN THROUGH THE IMP CEILING, OUT TO THE ROOF

SOME HEAVY DUTY STAINLESS STEEL PULLIES IN ITS RAW STATE

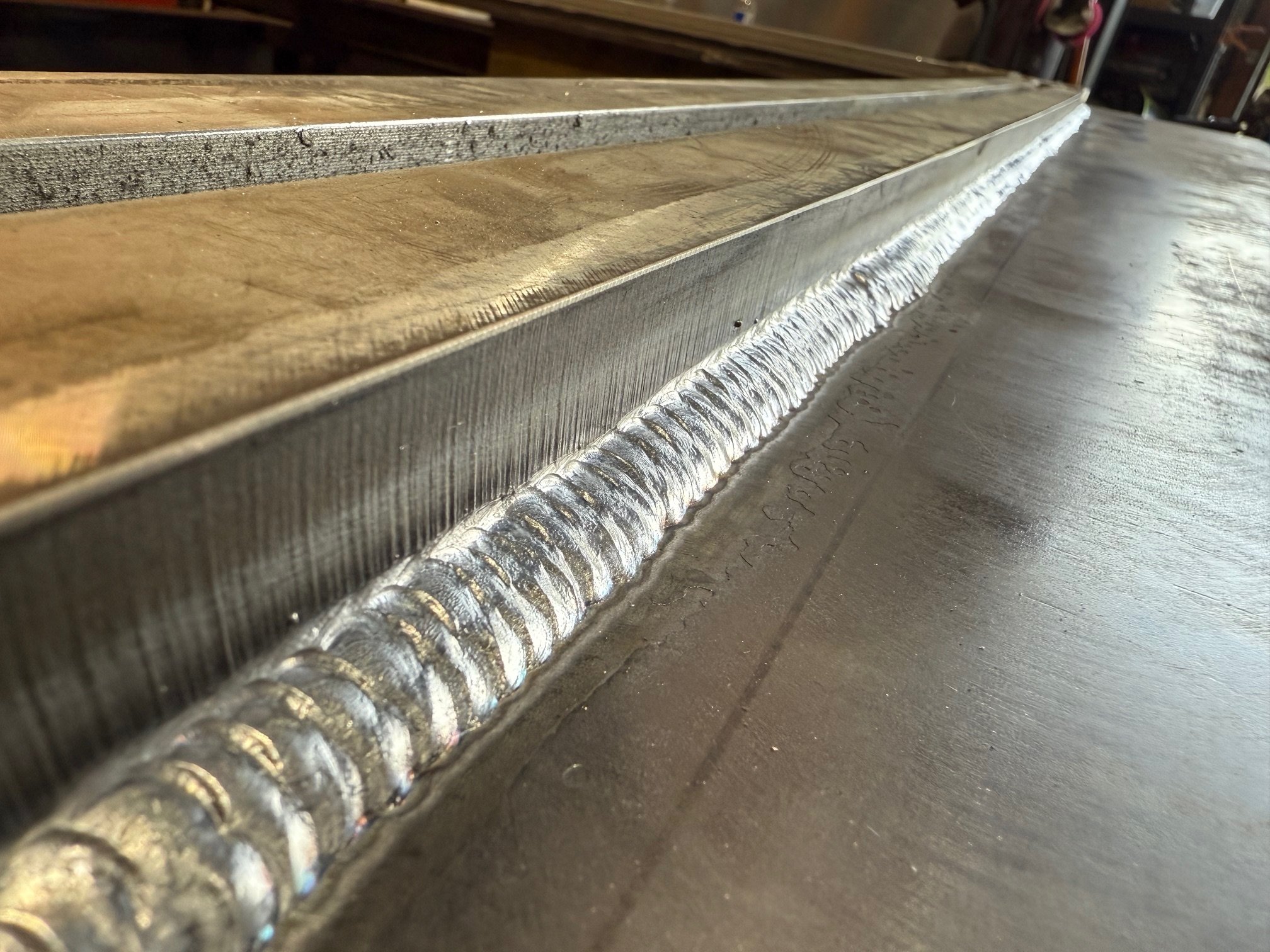

GETTING A NICE HOT PASS IN, LOVE THE COLORS!

ALL WELDED OUT

ALL 10 WELDED WITH IN SPEC AND DELIVERED TO THE CUSTOMER

HERES A FUN PIPE JOB, TIEING- IN SOME 4IN SCH 40 GLYCOL LINES FROM A CHILLER

PIPE SUPPORTS, INSTRUMENT WELD-O-LETS, YOU NAME IT!

A RUN OF 12 CUSTOM PALLET BANDS THE GUYS GOT ALL WELDED UP PRECISELY

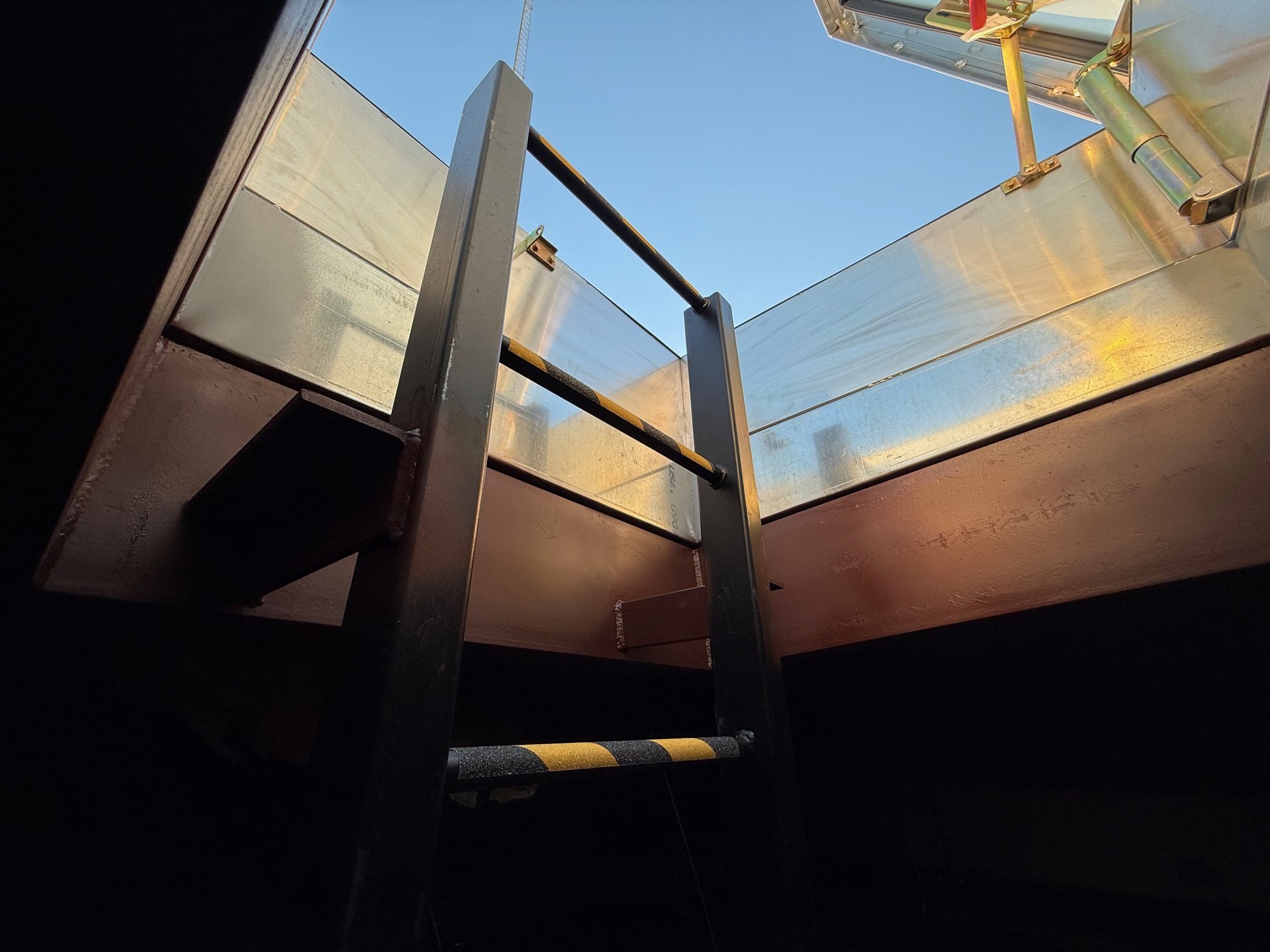

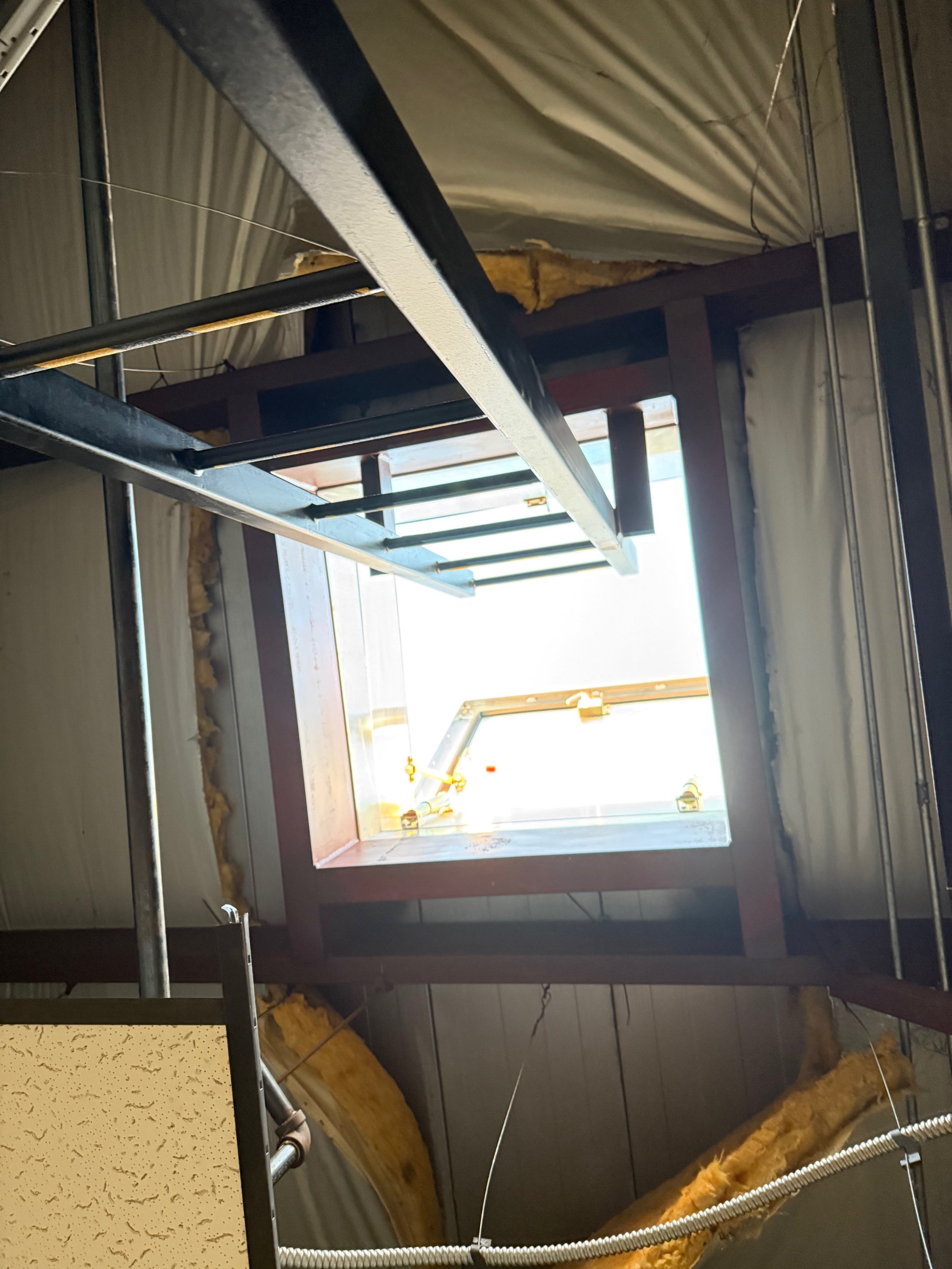

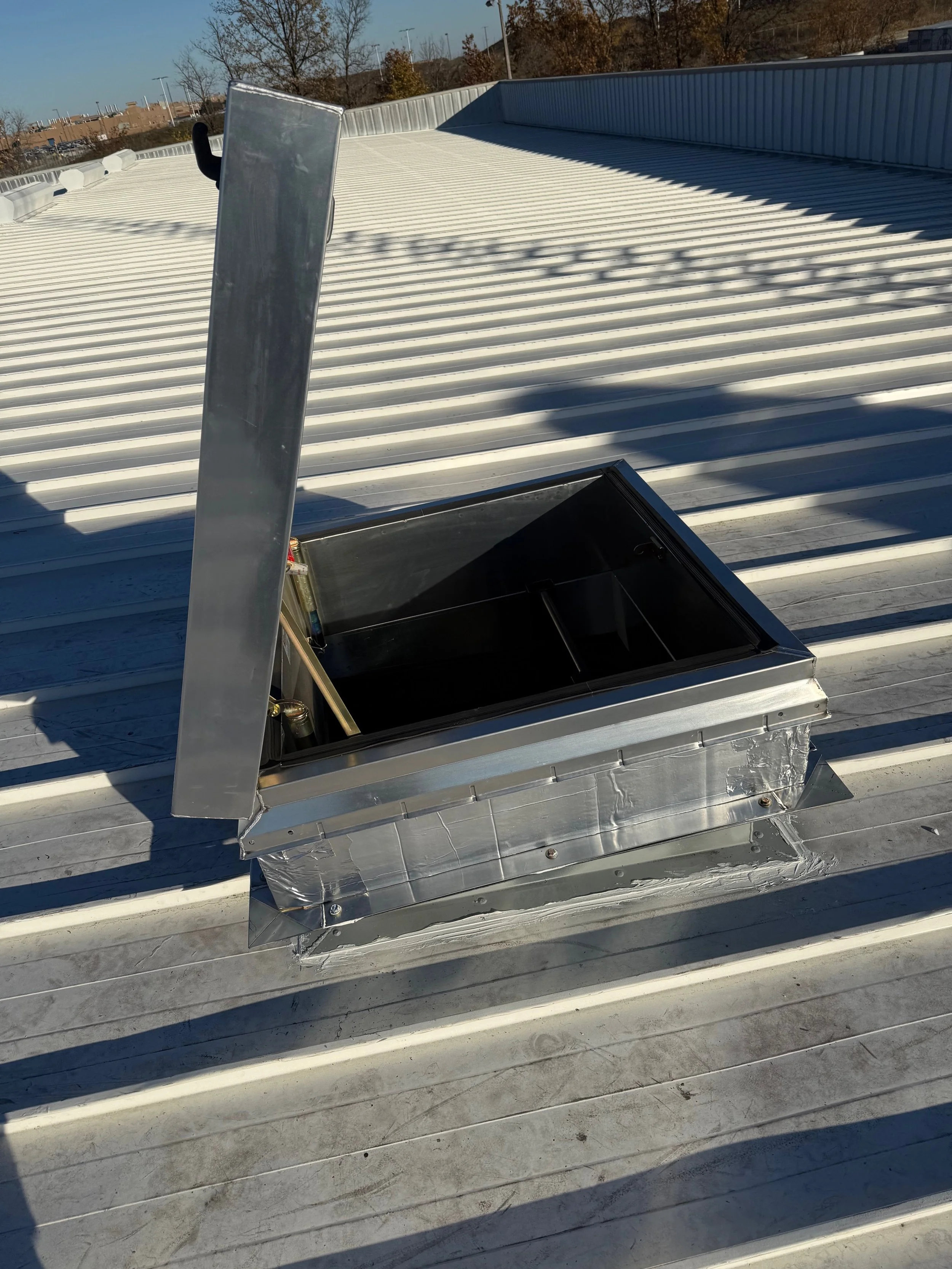

THIS WAS A ROOF ACCESS AND LADDER INSTALL JOB WE ENGINEERED

WE FABRICATED OUR RTU TO ENGINEERED PLANS AND FIT JUST RIGHT

WE DESIGNED THE RTU CURB AND INSTALLED THE HATCH

ALSO NEEDED AN EXTERNAL ALUMINUM LADDER WE FABRICATED IN THE SHOP AND INSTALLED IN THE FIELD

1" 1/4 STAINLESS FULL WELDOUT AND THEN MACHINED

WE CAN HANDLE YOUR HEAVY DUTY STAINLESS!

INSIDE BRACING WELD JOINT IN OUR INDUSTRIAL DOORS

CUSTOM STAINLESS STEEL WORK, WE CUT IT, THEN DESIGNED IT

FINAL RESULT HERE

STAINLESS STEEL SHAFT FOR FOOD GRADE PROCESSOR WE WELDED TO SPEC FOR OUR MACHINE SHOP TO FINISH